And they’re critical for big computer systems as well. As electronic devices become smaller and more ubiquitous, “putting more transistors on a chip is the way we can continue to bring more value, more functionality, lower cost and lower power consumption,” he explains. He sees a promising future for adding lots more transistors, the minute engines of computation. Khare, who’s responsible for all semiconductor research at IBM, believes the challenges of physics can be overcome.

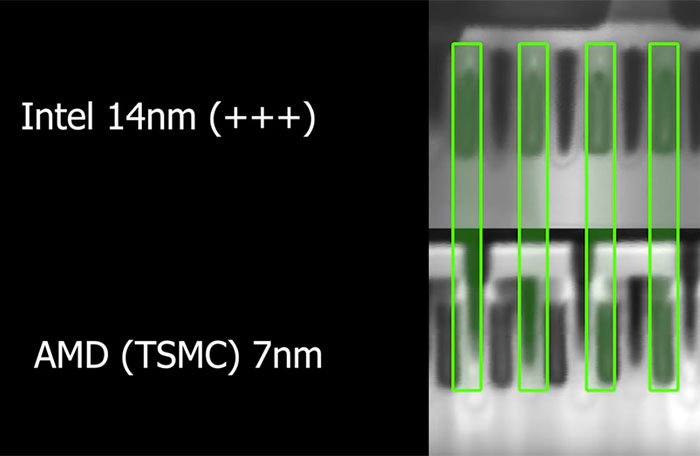

Increasing the number of circuits on silicon chips, say critics, has reached its limits, and computing will stall at its current level until a substitute approach can be found. But in recent years the progression has been slowed, some say stopped, by the laws of physics. That phenomenon - which became known as Moore’s Law - meant faster, more powerful computers. if the actual output drive were current-controlled by running the output transistor segments as if they were segments of a current mirror).īy only driving a selected subset of the gates, a desired width (and hence drive strength) can be achieved.For decades, the number of tiny transistors studding integrated circuit chips has doubled every two years. This particular design also shows a cascoded transistor, which might be desired in some cases (e.g. Note that each gate is separate (although I connected them to the same net), sources/drains are shared to save space, and everything's in the same diffusion (with dummies) for better matching.

#Transistor size driver#

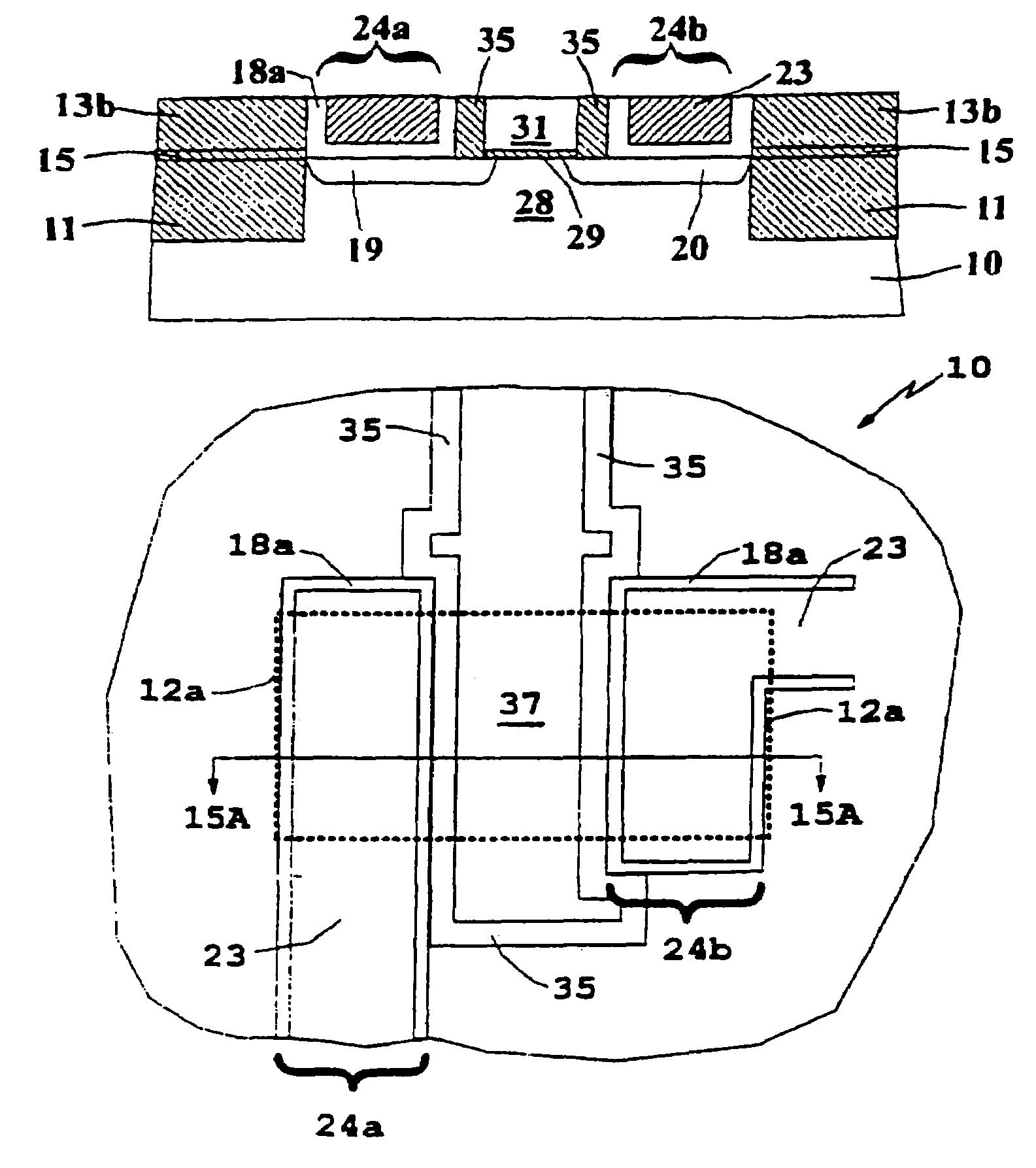

I'd imagine that output driver transistors (as opposed to fast, small core transistors) would be longer, wider, and perhaps have additional protection to protect against latchup and other damage induced by the outside world. I don't have an image of an output driver that I'm allowed to share, but the diagram below shows how this kind of layout can be done (using low-voltage core transistors in a 180 nm process from TSMC).

These fingers connect to parallel sources and drains, so when all of the gates turn on together, the arrangement acts as a transistor whose effective width is the sum of the constituent parts. The approach to do this is alluded to in the datasheet snippet you linked, which mentions "fingers", or separate parallel gates in a wide MOSFET that forms the output driver. I'd presume this is the same thing, or isn't it? Here's an excerpt from the datasheet of such an ASIC: I've seen ASICS on which you can select a drive strength. I'm assuming the author means on-the-fly adjustment, and not manufacturing adjustment. How this adjusting the drive transistor size is accomplished.

#Transistor size series#

Figure 36.5 shows a half-series transmission line with a series terminated driver and load. The impedance of the ON drive transistor acts as the termination. The drive transistor size can be adjusted so that it produces a half amplitude transition There is no need for a separate series resistor if the driving voltage source impedance can be controlled to be equivalent I have, however, recently seen the following passage in Right the First Time Vol.1 by Lee Ritchey and John Zasio:

One just needs to add a source-series terminator, which added together with the driver's output impedance equals the line impedance. The source-terminated reflected wave switching scheme is a familiar one.

0 kommentar(er)

0 kommentar(er)